References

Innovation, customer satisfaction and quality are at the centre of our business activities. A look at the following excerpts from our customer list and the respective projects will give you an overview of the international use of our products.

Our customers (extract)

Our reference systems

Heat-resistant stack press for the production of silicone seals

With two levels and heat-insulated support plates, this special press can be used to press moulds at up to 450 °C for casting special silicone moulds. The target pressure and holding time can be set digitally using the PLC control system. The control system monitors and regulates the moulding pressure fully automatically. If the contact pressure changes during the holding time (e.g. due to the slowly cooling mould), the force is automatically readjusted. A manufacturer of speciality gaskets is already successfully using several of these machines in multi-shift production.

200 tonne special press for the dismantling of nuclear power plants

This special press is used to compress radioactively contaminated filter mats from the dismantling of nuclear power plants. It is necessary to reduce the volume to a minimum for economical final disposal. The large pressing plates, which are guided in parallel by bolts, distribute the pressing force over as large an area as possible. To increase operator safety, the system is also equipped with a 2-hand control panel. Another special feature of this special press is that it can be used in two ways: the pressing plates can be removed using a conversion kit and an extendable roller carriage can be fitted, which can be used to press steel drums. To ensure that the press can be used for as long as possible at several dismantling plants, the design is such that the machine can be transported horizontally in a transport container for low-level radioactive equipment.

Special press made of V4A stainless steel for the pharmaceutical industry

This special press for a well-known manufacturer in the pharmaceutical industry is used to crush a solid raw material in the production process of creams. The machine is designed for use in a clean room and is made entirely of V4A stainless steel. It is operated via a 2-hand control panel, with the pressing process taking place behind a protective polycarbonate housing.

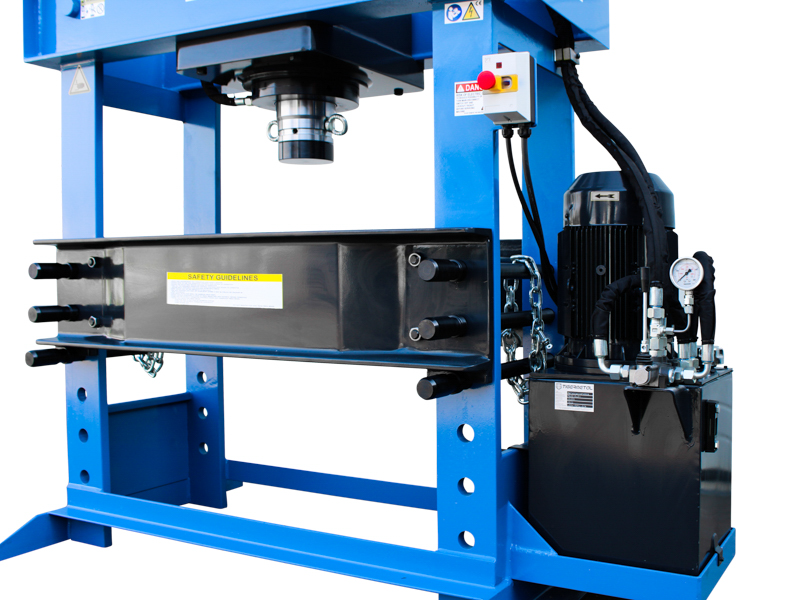

200 tonne press for international construction site containers

This 200 tonne press is designed to be installed in shipping containers as a mobile workshop. The special requirements here were a reduction in the overall height of the system and a drive that can be operated flexibly in international power grids outside Europe at 60 Hz and other voltages. As part of the mobile workshop, the hydraulic press travels with the container from construction site to construction site and is an important component on tunnelling sites. The machine is being built in series for a renowned manufacturer of tunnelling machines and has already been used in Egypt and Canada.

Joining station for diesel pumps

For the assembly of large diesel pumps, the customer required the cylinder head cover to be pre-tensioned using a hydraulic press so that the cylinder head bolts can be fitted during assembly. For this purpose, a press is integrated into a roller conveyor, which applies the necessary compressive force to the pump housing on the assembly line. The roller conveyor and press were completely pre-assembled by Tigermetal in the factory, including the electrical control and hydraulic unit, so that the unit only had to be integrated into the roller conveyor at the customer's site.